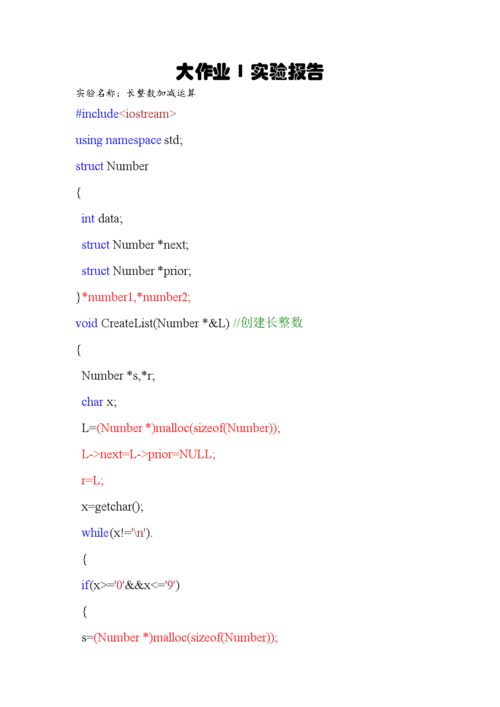

加法程序代码

Title: Understanding Additive Manufacturing and its Impact on Industries

Introduction to Additive Manufacturing

Additive Manufacturing (AM), commonly known as 3D printing, is a transformative technology that fabricates threedimensional objects layer by layer from digital models. Unlike traditional subtractive manufacturing methods that involve cutting away material from a solid block, AM builds objects layer by layer, adding material precisely where needed. This revolutionary approach offers numerous advantages, including increased design flexibility, reduced waste, and faster production cycles.

Key Principles of Additive Manufacturing

1.

Layering Process

: Additive manufacturing builds objects by depositing material layer upon layer, guided by a digital design file. This layerbylayer approach enables intricate geometries and complex internal structures that are difficult or impossible to achieve with traditional methods.2.

Material Variety

: Additive manufacturing supports a wide range of materials, including plastics, metals, ceramics, and composites. Each material has its unique properties, enabling manufacturers to select the most suitable material for their specific application.3.

Design Freedom

: Unlike traditional manufacturing, which often imposes constraints on design due to manufacturing limitations, AM offers unparalleled design freedom. Complex geometries, lightweight structures, and customized components can be easily produced using additive manufacturing technologies.4.

OnDemand Production

: Additive manufacturing facilitates ondemand production, allowing manufacturers to produce parts as needed, reducing inventory costs and lead times. This justintime manufacturing approach is particularly beneficial for industries with fluctuating demand or those requiring highly customized products.Applications Across Industries

1.

Automotive Industry

: Additive manufacturing is revolutionizing the automotive industry by enabling rapid prototyping, customized parts production, and lightweight component fabrication. Automakers use AM for producing prototypes, tooling, and enduse parts, leading to faster innovation cycles and improved vehicle performance.2.

Aerospace and Defense

: Additive manufacturing has significant applications in the aerospace and defense sectors, where lightweight, highperformance components are critical. AM technologies are used to manufacture complex aircraft parts, rocket engines, and unmanned aerial vehicle (UAV) components, reducing weight, improving fuel efficiency, and enhancing mission capabilities.3.

Medical and Healthcare

: In the medical field, additive manufacturing is transforming patient care through personalized implants, prosthetics, and surgical guides. Surgeons can now design and fabricate patientspecific implants tailored to individual anatomies, improving surgical outcomes and patient comfort.4.

Consumer Goods

: Additive manufacturing is reshaping the consumer goods industry by enabling mass customization and product personalization. Companies can offer tailored products to individual consumers, driving customer engagement and brand loyalty. From custom footwear to personalized electronics, AM is unlocking new possibilities in consumer product design and manufacturing.

5.

Architecture and Construction

: Additive manufacturing is increasingly used in architecture and construction for rapid prototyping, architectural modeling, and even fullscale building construction. 3Dprinted structures offer design freedom, reduced material waste, and faster construction times, making them attractive for innovative architectural projects and sustainable building practices.Challenges and Future Outlook

While additive manufacturing offers numerous benefits, it also faces several challenges, including material limitations, process scalability, and postprocessing requirements. Addressing these challenges will require continued research and development efforts to unlock the full potential of additive manufacturing across industries.

Looking ahead, additive manufacturing is poised to become even more integral to the manufacturing landscape, with advancements in materials, process optimization, and digital design tools driving further innovation. As the technology matures and adoption rates increase, additive manufacturing will continue to revolutionize industries, offering unprecedented opportunities for innovation, customization, and sustainable manufacturing practices.

In conclusion, additive manufacturing represents a paradigm shift in manufacturing, offering unparalleled design freedom, ondemand production capabilities, and transformative applications across industries. Embracing additive manufacturing technologies will empower businesses to innovate faster, produce more efficiently, and unlock new opportunities for growth in the increasingly competitive global marketplace.

References:

"Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing" by Ian Gibson, David W. Rosen, and Brent Stucker.

"Additive Manufacturing: Opportunities and Constraints" by OECD Directorate for Science, Technology, and Innovation.

"The 3D Printing Handbook: Technologies, Design, and Applications" by Ben Redwood, Filemon Schöffer, and Brian Garret.

本文 新鼎系統网 原创,转载保留链接!网址:https://acs-product.com/post/16103.html

免责声明:本网站部分内容由用户自行上传,若侵犯了您的权益,请联系我们处理,谢谢!联系QQ:2760375052 版权所有:新鼎系統网沪ICP备2023024866号-15